Joining 3mm aluminum composite panels (ACP) is a critical process in construction and design, ensuring structural integrity and aesthetic appeal. This guide will cover various methods, considerations, common mistakes to avoid, and maintenance requirements, providing you with a thorough understanding of how to join 3mm aluminum composite panels effectively.

Understanding Aluminum Composite Panels

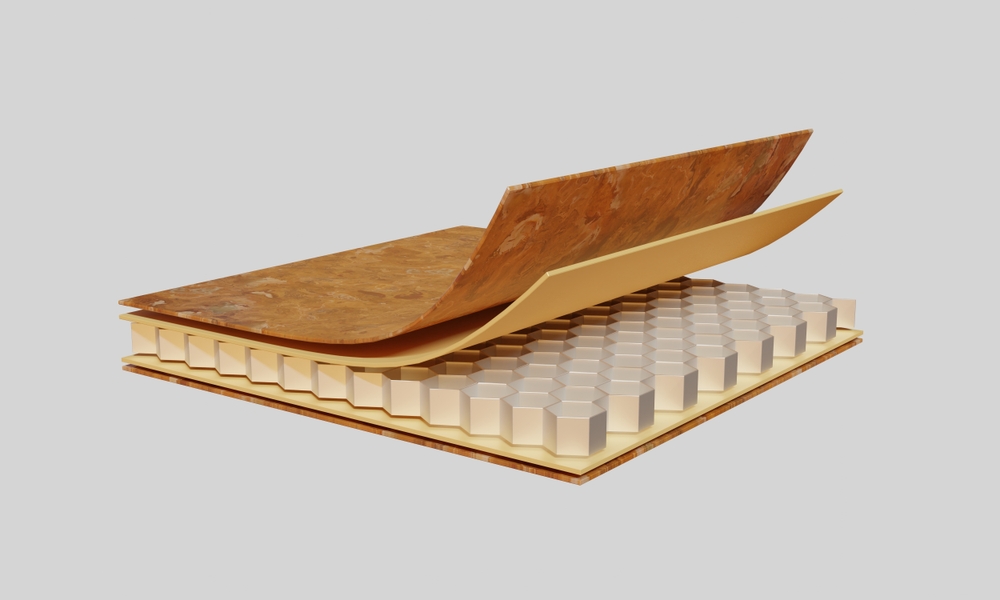

Aluminum composite panels are made of two thin layers of aluminum enclosing a non-aluminum core. They are widely used for facades, signage, and interior applications due to their lightweight nature, durability, and versatility. The joining process is essential for ensuring that the panels perform well under various environmental conditions.

Key Benefits of Using 3mm Aluminum Composite Panels

- Lightweight: Easy to handle and install.

- Durable: Resistant to weathering and corrosion.

- Aesthetic Flexibility: Available in various colors and finishes.

- Insulation Properties: Provides thermal insulation.

Mechanical Fastening Methods

Mechanical fastening is one of the most common ways to join 3mm aluminum composite panels. Here are three effective methods:

1. Riveting

Riveting involves using aluminum rivets to secure the panels together.

- Materials Needed:

- Aluminum blind rivets (diameter 4-5mm)

- Rivet gun

- Washers

- Procedure:

- Pre-drill holes slightly larger (0.1-0.2mm) than the rivet diameter.

- Space rivets at intervals of 200-300mm along the joint, reducing to 150mm at corners.

- Use washers under rivet heads to distribute load evenly.

2. Screwing

Self-tapping screws can also be employed for joining panels.

- Materials Needed:

- Stainless steel or coated self-drilling screws (#8 or #10)

- Neoprene washers

- Drill

- Procedure:

- Pre-drill pilot holes to prevent deformation.

- Space screws 300-400mm apart on straight runs.

- Ensure proper torque control; stop when the washer starts compressing.

3. Profile Systems

Aluminum profiles (H, U, or L-shaped) provide clean joints between panels.

- Materials Needed:

- Aluminum profiles

- Structural silicone sealant

- Procedure:

- Use H-profiles for butt joints and U-channels for edges.

- Allow a clearance of 2-3mm in profiles for thermal movement.

- Seal joints with structural silicone to prevent moisture infiltration.

Adhesive Bonding Methods

Adhesive bonding is another effective method for joining aluminum composite panels.

Surface Preparation

Proper surface preparation is crucial for effective adhesive bonding.

- Steps:

- Clean surfaces with isopropyl alcohol.

- Lightly abrade bonding areas with sandpaper (120-grit).

- Remove all dust with a lint-free cloth.

Adhesive Selection

Choose the right adhesive based on your application:

- Recommended Adhesives:

- MS Polymer adhesives (for exterior use)

- Two-component polyurethane adhesives

- Structural silicone sealants

Application Process

Follow these steps for applying adhesive:

- Apply adhesive in a continuous zigzag pattern.

- Maintain a bead width of 6-8mm and thickness of 2-3mm.

- Use spacer tape to ensure uniform bond line.

- Clamp or support until initial cure; full cure typically takes 24-48 hours.

Joint Design Considerations

When joining aluminum composite panels, consider the following design aspects:

Expansion Joints

To accommodate thermal expansion:

- Calculate thermal expansion at approximately

- 1.2 mm

- 1.2 mm per meter for a

- 50∘C

- 50

- ∘

- C temperature change.

- Leave a minimum

- 3 mm

- 3 mm gap between panels.

Weather Protection

Ensure that joints are protected from weather elements:

- All horizontal joints should have a minimum slope of

- 1:50

- 1:50 to shed water.

- Use EPDM gaskets in exposed locations and apply weather sealant on external joints.

Structural Support

To enhance stability:

- Maximum unsupported span should not exceed

- 600 mm

- 600 mm.

- Use backing plates that are at least

- 2 mm

- 2 mm thick.

Common Mistakes to Avoid

Avoid these common pitfalls when joining aluminum composite panels:

- Over-tightening Fasteners: This can deform the panel; use proper torque settings.

- Incompatible Metals: Avoid using metals that can cause galvanic corrosion.

- Extreme Weather Conditions: Do not join panels in extremely cold or hot conditions as it can affect adhesion and performance.

Safety Measures

Ensure safety during installation by following these guidelines:

- Wear appropriate personal protective equipment (PPE), including gloves and eye protection.

- Use proper lifting techniques for large panels to prevent injury.

- Ensure adequate ventilation when using adhesives to avoid inhalation of fumes.

Maintenance Requirements

Regular maintenance will help prolong the life of your aluminum composite panel installation:

- Inspect joints annually for sealant degradation and repair as necessary.

- Check mechanical fasteners for loosening and tighten if needed.

- Clean joints regularly to remove debris accumulation that can lead to moisture retention.

Conclusion

Knowing how to join 3mm aluminum composite panels effectively is essential for achieving durable and visually appealing installations. By understanding mechanical fastening methods, adhesive bonding techniques, joint design considerations, and common mistakes to avoid, you can ensure a successful project outcome. Regular maintenance and adherence to safety measures will further enhance the longevity of your installation.

By following this comprehensive guide, you will be well-equipped with the knowledge needed to tackle your aluminum composite panel projects confidently.

Leave a Reply