Aluminium Composite Panels (ACPs) are widely used in construction and architectural design due to their aesthetic appeal, lightweight properties, and durability. However, to ensure safety and performance, ACPs must comply with various codes and standards. This article explores the relevant codes governing ACPs, focusing on international and regional standards that dictate their use in construction.

What is the Code for Aluminium Composite Panel?

The term “code for aluminium composite panel” refers to a set of guidelines and standards established by various organizations to ensure the safety, performance, and quality of ACPs. These codes cover aspects such as fire resistance, structural integrity, thermal performance, and environmental impact. Compliance with these codes is crucial for manufacturers, architects, and builders to ensure that ACPs meet the necessary safety requirements.

International Standards for Aluminium Composite Panels

1. ASTM Standards

The American Society for Testing and Materials (ASTM) provides several key standards relevant to ACPs:

- ASTM E84: This standard measures the surface burning characteristics of building materials. It determines the flame spread index and smoke developed index, which are critical for assessing fire safety in both interior and exterior applications.

- ASTM E662: This standard evaluates the specific optical density of smoke generated by materials during combustion. It is essential for public safety considerations in buildings.

- ASTM E1354: This standard assesses heat release rates and visible smoke production during a fire scenario, providing a comprehensive evaluation of fire performance.

2. ISO Standards

The International Organization for Standardization (ISO) also sets forth important standards:

- ISO 1182: This standard tests the reaction to fire of building materials, determining their non-combustibility and fire resistance properties.

- ISO 9705: A full-scale room test that simulates real-world fire scenarios to evaluate the fire performance of surface products.

- ISO 12944: This standard defines corrosion protection measures for coated steel structures, which can be applicable to ACPs used in corrosive environments.

3. Common International Codes

Several other international codes are relevant to ACPs:

- EN 13501-1: This European standard classifies construction products based on their fire performance characteristics.

- BS 476: A British standard that includes various fire tests on building materials and structures.

- NFPA 285: A standard fire test method from the National Fire Protection Association that evaluates the fire propagation characteristics of exterior wall assemblies.

Regional Specific Codes

1. United States Regulations

In the United States, two primary codes govern ACP usage:

- International Building Code (IBC): This code outlines requirements for exterior walls, including fire classification, structural performance, and wind load resistance.

- National Fire Protection Association (NFPA) Standards: NFPA 285 is particularly critical for multi-story building facades as it evaluates how well materials prevent fire from spreading vertically.

2. European Union Standards

In Europe, compliance with specific regulations is mandatory:

- European Construction Product Regulation (CPR): Requires that construction products meet certain performance criteria before they can be marketed in the EU.

- Eurocode Standards: Provide guidelines on structural design aspects related to various materials, including ACPs.

3. Australian Standards

Australia has its own set of regulations:

- Australian Building Codes Board (ABCB): Regulates building materials’ compliance with safety standards.

4. Middle East Regulations

In the Middle East, civil defense regulations focus on fire safety measures specific to local building codes.

Key Performance Parameters in Codes

When assessing ACPs under these codes, several key performance parameters are evaluated:

| Parameter | Description |

| Fire Rating | Classification based on flame spread potential |

| Combustibility | Determines if a material will ignite or support combustion |

| Smoke Development | Evaluates smoke generation during combustion |

| Structural Integrity | Assesses ability to withstand loads without failure |

| Thermal Insulation | Measures effectiveness in thermal performance |

| Wind Load Resistance | Evaluates ability to withstand wind forces |

Compliance Testing Methodologies

To ensure compliance with these codes, various testing methodologies are employed:

1. Testing Protocols

- Accelerated Aging Tests: Simulate long-term exposure to environmental conditions.

- Thermal Cycling: Tests material response to extreme temperature variations.

- UV Exposure Testing: Evaluates resistance to ultraviolet light degradation.

- Moisture Resistance Evaluation: Assesses how well materials resist moisture intrusion.

- Mechanical Performance Assessment: Tests strength under load conditions.

2. Key Measurement Criteria

Testing protocols measure several criteria:

| Measurement Criteria | Description |

| Surface Burning Characteristics | Evaluates how quickly flames spread across surfaces |

| Smoke Density | Measures how much smoke is produced during combustion |

| Flame Spread | Assesses how far flames travel along a material |

| Heat Release Rate | Quantifies energy released during combustion |

| Structural Deformation | Analyzes changes in shape or integrity under stress |

| Thermal Conductivity | Measures heat transfer efficiency |

Compliance Classification Levels

ACPs are classified based on their performance in various categories:

1. Fire Rating Classifications

Fire ratings categorize materials based on their flame spread characteristics:

- Class A: Lowest flame spread; suitable for high-risk applications.

- Class B: Moderate flame spread; acceptable for many commercial applications.

- Class C: Higher flame spread; generally used in less critical areas.

Special ratings may be assigned for specific applications requiring enhanced safety measures.

2. Performance Categories

ACPs can also be classified based on intended use:

- Interior Use

- Exterior Cladding

- Structural Applications

- High-Rise Buildings

- Industrial Environments

Specialized Considerations

When selecting ACPs based on code compliance, consider specialized factors:

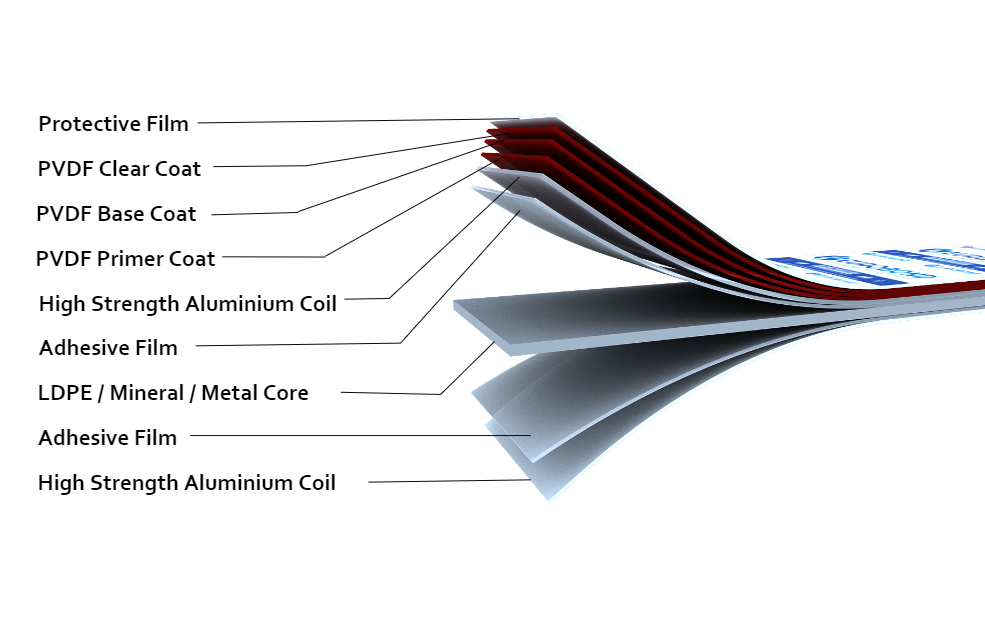

1. Material Composition Evaluation

Evaluating material composition is crucial for ensuring compliance with safety standards:

- Core Material Testing

- Aluminum Skin Analysis

- Bonding Agent Performance

- Additives and Fire Retardants

2. Environmental Factors

Assessing environmental resilience is essential:

- Climate Resistance

- Temperature Performance

- UV Degradation Resistance

- Chemical Exposure Evaluation

Documentation and Certification

To demonstrate compliance with applicable codes and standards, proper documentation is necessary:

1. Required Documentation

Manufacturers should provide the following documents:

- Manufacturer’s Test Reports

- Third-party Certification

- Material Performance Statements

- Compliance Certificates

2. Certification Bodies

Several organizations provide certification for ACPs:

- Underwriters Laboratories (UL)

- International Code Council (ICC)

- European Technical Assessment (ETA)

- National Accreditation Bodies

Emerging Trends and Future Developments

As technology evolves, so do the standards governing aluminium composite panels. Key trends include:

- Increased Focus on Sustainable Materials: Manufacturers are exploring eco-friendly options that meet stringent environmental regulations.

- Enhanced Fire Safety Technologies: Innovations in materials aim to improve fire resistance without compromising aesthetics.

- Improved Composite Material Formulations: Research into new composites enhances strength while reducing weight.

- Smart Material Integration: Incorporating smart technologies into ACPs for better monitoring and response capabilities.

- Advanced Testing Methodologies: Development of more rigorous testing protocols ensures higher safety standards.

Practical Recommendations

For those involved in selecting or specifying aluminium composite panels, consider these practical recommendations:

- Always consult local building authorities regarding specific regional requirements.

- Work with certified manufacturers who provide comprehensive testing documentation.

- Obtain detailed information about project-specific performance needs.

- Verify compliance with current regulations before finalizing material selections.

Conclusion

Understanding “is code for aluminium composite panel” encompasses a broad spectrum of international and regional standards designed to ensure safety, performance, and quality in construction applications. By adhering to these established codes, manufacturers and builders can significantly enhance the reliability of ACPs while contributing to safer built environments. As regulations continue to evolve alongside technological advancements, staying informed about these changes will be crucial for all stakeholders involved in the use of aluminium composite panels in construction projects.

Leave a Reply