Introduction: ACP—A Material That Bends but Doesn’t Break

Let’s dive right in—what exactly is an aluminium composite panel, or as the cool kids call it, ACP? Think of it as the multitool of modern construction and design: a sleek sandwich of two aluminium layers surrounding a core (usually polyethylene or mineral). It’s lightweight yet sturdy, flexible yet durable—a true overachiever in the world of building materials.

ACP is everywhere. Look up at skyscrapers, and you’ll see it clad across facades. Stroll through a shopping mall, and it’s probably in the signage. It’s a favorite for architects, designers, and engineers alike. But here’s the twist (pun intended)—sometimes ACP needs to bend to fit bold architectural visions or snug into intricate signage designs.

Why bend ACP, you ask? Well, think of it as teaching a straight arrow to curve. Bending allows ACP to achieve organic shapes, meet structural demands, and create visually stunning designs. So, buckle up as we unravel the secrets to bending ACP with finesse.

Properties of Aluminium Composite Panels: What Makes ACP Special?

Before you can bend it, you need to understand it. Let’s break down what makes ACP so unique.

Composition: A Marvel of Modern Engineering

At its core (literally), ACP is a sandwich. It consists of:

- Aluminium Layers: Provide strength and a smooth finish.

- Polyethylene or Mineral Core: Offers flexibility and insulation.

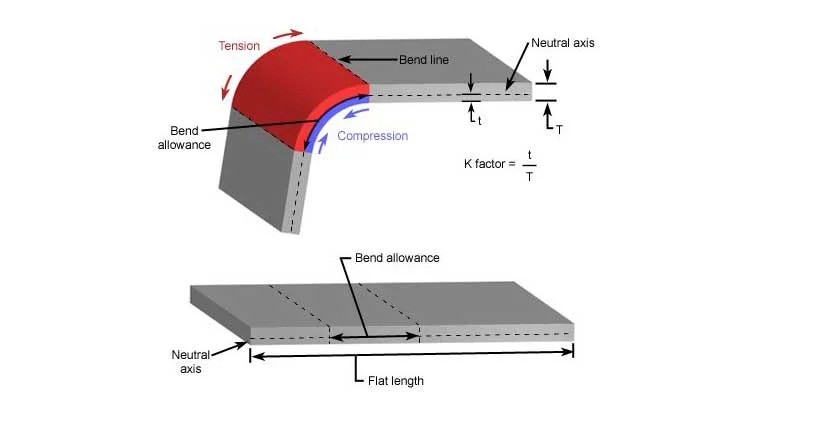

Flexibility and Durability

Despite its rigid appearance, ACP is surprisingly flexible. This property is what makes it a favorite for curved designs and cladding. Yet, it’s tough enough to withstand weather, wear, and tear—talk about a material with dual personalities!

Factors Influencing Bendability

Not all ACPs are created equal. Their bendability depends on:

- Thickness: Thicker panels are less flexible.

- Core Material: Polyethylene cores bend more easily than mineral ones.

- Coating: Protective films or finishes can affect the bending process.

Methods to Bend ACP: A Tale of Techniques

Now that we know the “what” and “why,” let’s tackle the “how.” Bending ACP can be an art and a science.

Mechanical Bending: The Workhorse Approach

Ever seen those hulking machines in fabrication workshops? That’s your mechanical bender.

- Press Brakes: These machines apply precise pressure to bend ACP at exact angles.

- Rolling Machines: Perfect for creating curves and arcs.

Pro Tip: To avoid creases or cracks, ensure the panel’s protective film stays on during the process. And don’t rush—smooth and steady wins the race!

Manual Bending: For DIY Enthusiasts

If you’re tackling a small project and can’t justify industrial machines, manual bending might work.

- How It’s Done: Apply consistent pressure along the bend line.

- Drawbacks: This method risks uneven bends or damage, so it’s not for the faint of heart (or hand).

CNC Routing and Folding: Precision Personified

CNC (Computer Numerical Control) machines are like the Michelangelo of ACP bending—they carve, fold, and bend with unmatched precision.

- V-Grooving Technique: A V-shaped groove is routed into the back, allowing the panel to bend neatly.

- Best For: Intricate designs or where absolute accuracy is a must.

Precautions While Bending ACP: Avoiding a Bend Gone Bad

Bending ACP isn’t just about brute force—it’s an art that requires care. Here’s what to watch out for:

- Cracking and Delamination: Avoid bending too sharply, or the layers might split like an overstuffed taco.

- Protective Film: Keep it on to prevent scratches or marks.

- Temperature Matters: Cold bending is faster, but hot bending can reduce stress on the material.

Tools and Equipment: Gearing Up for Success

To bend ACP like a pro, you need the right tools. Here’s a quick rundown:

| Tool | Purpose | Pros | Cons |

| Press Brakes | Precise angle bends | Consistency, efficiency | Expensive |

| V-Groove Routers | Clean, sharp folds for intricate designs | High precision | Steep learning curve |

| Rolling Machines | Smooth, curved bends | Ideal for arcs | Limited to curves |

| Heat Guns | Aids in hot bending | Reduces risk of cracking | Time-consuming |

Common Mistakes to Avoid: Learn from Others’ Oops Moments

Even seasoned pros can slip up. Here are some common pitfalls:

- Over-Bending: This can expose the core, leading to aesthetic and structural issues.

- Using the Wrong Tools: Press brakes for intricate folds? Nope! Use a V-groove router instead.

- Ignoring Manufacturer Guidelines: ACPs come with bending recommendations—follow them like a recipe.

FAQs: Clearing the Air on ACP Bending

Can ACP Be Bent Without Professional Tools?

Yes, but be cautious. Manual bending works for small projects, but uneven results are a risk.

What Is the Smallest Bending Radius for ACP?

The minimum radius depends on the panel’s thickness. As a rule of thumb, don’t bend tighter than 20 times the panel’s thickness.

Does Bending Affect Structural Integrity?

Not if done correctly. Improper techniques, however, can lead to delamination or cracks.

Real-World Applications: ACP in Action

Want to see ACP bending at its finest? Check out these examples:

- Modern Architecture: Think curvy facades and seamless transitions in skyscrapers.

- Art Installations: Sculptures and installations that challenge conventional forms.

- Signage: Sleek, folded designs that grab attention.

Design trends increasingly embrace fluid, organic shapes—ACP is the perfect canvas.

Alternatives to Bending ACP: When the Curve Doesn’t Fit

Sometimes bending isn’t the best option. Consider these alternatives:

- Pre-Formed Panels: Buy ACPs that are already curved or angled.

- Flexible Materials: For tight bends, materials like polycarbonate may work better.

Conclusion: Bending ACP Like a Pro

Bending aluminium composite panels is both an art and a science. It requires the right tools, techniques, and a fair bit of patience. By understanding ACP’s properties, following best practices, and learning from common mistakes, you can achieve bends that are as functional as they are beautiful.So, whether you’re designing a futuristic building, crafting eye-catching signage, or just experimenting with materials, ACP’s flexibility has you covered—literally and figuratively. As they say, bend it like… ACP!

Leave a Reply